What factors should procurement teams consider when selecting a wooden balance bike manufacturer?

You’re a procurement manager trying to source wooden balance bikes. You face a sea of online suppliers, all making big promises. A wrong choice could lead to quality nightmares and delayed shipments.

Procurement teams must evaluate a manufacturer’s safety certifications, production capacity, commitment to sustainability, willingness to undergo third-party audits, and their capabilities for innovation. This comprehensive approach ensures a reliable, long-term partnership.

From my years of running a factory, I’ve seen buyers make the same mistake over and over: they focus only on the price. An experienced buyer like Sophia knows better. She has a checklist. She understands that the true cost of a product includes its quality, its compliance, and the reliability of the company making it. Choosing a partner is one of the most important decisions you’ll make. It determines not just the success of one product line, but the health of your brand. Let’s walk through the key factors on that professional buyer’s checklist.

How do leading wooden balance bike manufacturers ensure product innovation and customization for clients?

You want to stand out in a crowded market. A generic, off-the-shelf product won’t cut it. But you worry that factories can’t deliver on custom designs or innovative ideas.

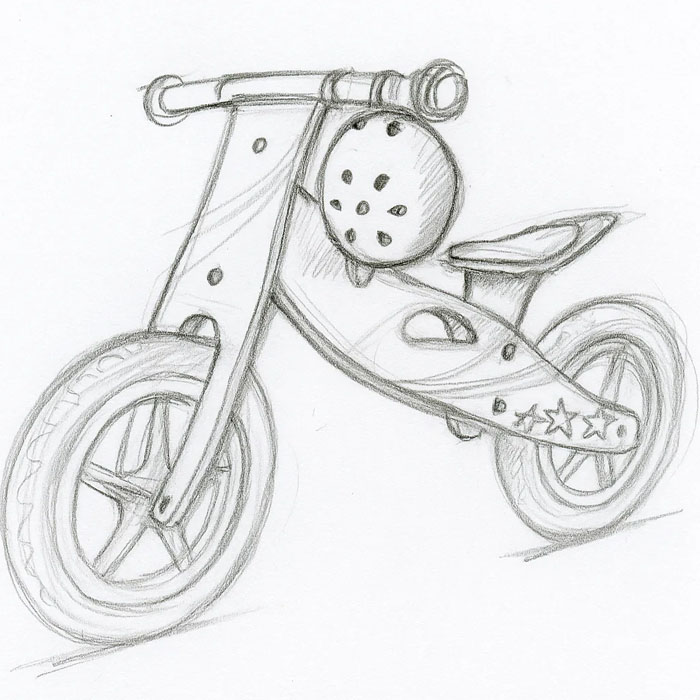

Leading manufacturers drive innovation with in-house design teams and offer both ODM and OEM services. They use CAD software for precision and provide physical samples to ensure the final product matches your vision perfectly.

Innovation is a partnership. A great manufacturer doesn’t just take orders; they provide solutions. When a client comes to me with an idea, my team and I act as consultants. We offer two main paths: ODM (Original Design Manufacturing) and OEM (Original Equipment Manufacturing). With ODM, you can choose one of our proven, safety-tested designs and brand it as your own. It’s fast and low-risk. With OEM, we build your unique design from the ground up. This is where a true partnership shines. We analyze your drawings for safety compliance, suggest material improvements, and optimize the design for manufacturing efficiency. This collaborative process ensures your unique product is not only beautiful but also safe, durable, and cost-effective to produce. Customization also extends to packaging, which is critical for brand identity.

OEM vs. ODM Services

| Service Type | Process | Best For |

|---|---|---|

| ODM | Select, brand, and sell our existing designs. | Brands wanting a fast market entry with a proven product. |

| OEM | We develop and manufacture your unique, custom design. | Brands wanting a completely unique product to stand out. |

Why is a third-party audit important when partnering with a wooden balance bike manufacturer?

The factory website looks great and the samples were perfect. But how can you be sure of what’s really happening on the production line thousands of miles away? You can’t afford to take their word for it.

A third-party audit provides unbiased, objective proof of a factory’s quality systems, ethical standards (like BSCI), and true production capacity. It’s a critical step in risk management before placing a large order.

As a factory owner, I welcome audits. In fact, I insist on them for large-scale partnerships. A manufacturer who resists an audit is hiding something. An audit is not about a lack of trust; it’s about building a foundation of professional trust. When an auditor sent by a major European client walks onto my floor, it’s an opportunity for me to demonstrate our commitment to excellence. They use a detailed checklist to verify everything. They inspect our Quality Management System to ensure we have checkpoints at every stage. They verify our social compliance certifications, like BSCI, to ensure our workers are treated fairly. They assess our machinery and workflow to confirm we can handle the order volume we promised. It’s an honest, transparent process that protects both sides of the partnership.

How do production capabilities of wooden balance bike manufacturers affect lead times and order fulfillment?

You’ve planned a major holiday promotion around your new balance bikes. The factory promised delivery, but now they are reporting delays. Your marketing campaign and your revenue are now seriously at risk.

A factory’s production capability—its machinery, skilled labor, and supply chain management—directly impacts its ability to fulfill orders on time. Strong capabilities mean reliable lead times, even during peak seasons.

Production capability is much more than the square footage of a factory. It is the engine of the entire business. Our capability is built on three pillars. First, modern equipment. We use computer-controlled CNC routers for cutting parts with perfect precision and automated finishing lines for consistent, safe coatings. This reduces human error and speeds up production. Second, a stable, skilled workforce. Our team has years of experience, which means higher quality and efficiency. Third, and most critically, supply chain management. We have strong, long-term relationships with our plywood and hardware suppliers. This means we can secure high-quality raw materials without unexpected delays. These factors combined allow us to give clients like Sophia an accurate lead time—usually 45 to 60 days—and stick to it. We also provide post-sale support, like supplying spare parts, because a good partnership doesn’t end when the container ships.

How do manufacturers address sustainability concerns in wooden balance bike production?

Your customers are smart. They want eco-friendly products, but they can spot "greenwashing" from a mile away. You need to offer a product whose sustainability claims are real and verifiable.

Reputable manufacturers prove their commitment to sustainability by using FSC-certified wood from responsibly managed forests. They also use non-toxic, water-based paints and implement waste-reduction programs in their factories.

Sustainability has moved from a selling point to a core requirement, especially in the toy industry. It’s a change I’ve built my business around. The most important pillar of our sustainability story is using wood with FSC (Forest Stewardship Council) certification. This isn’t just a sticker; it’s a guarantee that the wood comes from a forest managed in an environmentally and socially responsible way. We then use exclusively water-based, non-toxic paints and lacquers. These are safer for the children playing with the bikes and for our workers and the environment. This focus on real, verifiable sustainability is a powerful business tool. Data from B2B platforms shows that factories with a clear eco-concept and brand story have a conversion rate nearly 41% higher than generic suppliers. When you can tell a parent a true story about protecting the planet, you build a connection that goes beyond price.

Conclusion

Selecting the right manufacturer requires looking past the unit price. Focus on their verifiable compliance, innovation process, audit readiness, and true commitment to sustainability. This creates a profitable, reliable, and "brand-safe" partnership.